The Process of Making Hardware

Centuries of Crafting Handmade Buckles, Pendants, Studs, Stirrups and Bits

All the hardware used on our Victorino products, is handmade and designed by José Victorino, who designs and hand-makes all the products in the Victorino range. From buckles, to bits and studs on the dog collars and saddles are all handmade. Making the hardware is an extremely long and detailed process.

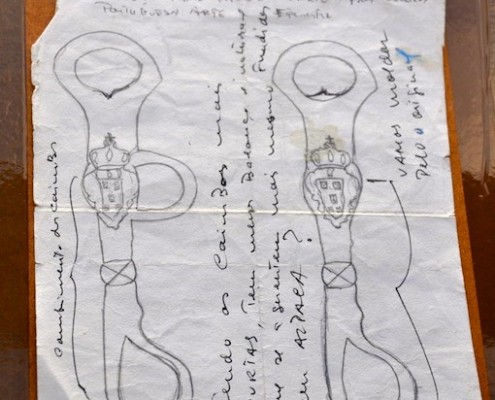

In the photograph you can see the original drawing for the bit for the Portuguese School of Equestrian Arte by Jose de Sousa

To visit the Portuguese School of Equestrian Art

The buckles and all the accessories used are made entirely by hand in Brass or Alpaca.

Each piece of hardware is firstly designed on paper and carefully drawn up, from each angle, with all the necessary detail. When the buckle, stud or bit is drawn and the design is finished, a mould of the hardware, whether it be the shanks (sides) of the bit, the bit mouthpiece, or a new design buckle, or stud, a new mould has to be made every time, for a new design, but which then can be used over and over again.

For example, when a bit is made, the shanks are molded first, then the mouthpiece is made, using the same principles, the mouthpiece is then soldered to the shanks and any other finishing touches are made.

Finishing

All the hardware is fully hand-made from casting to finishing, with metal alloy, which is composed of five dissimilar metals (Copper, Nickel, Zinc, Lead and Tin) which is called  Alpaca, in Portuguese. There is evidence that this alloy (Alpaca) causes a chemical reaction in the horses mouth making it very good and very relaxing for the horse and stimulates oral saliva.

Alpaca, in Portuguese. There is evidence that this alloy (Alpaca) causes a chemical reaction in the horses mouth making it very good and very relaxing for the horse and stimulates oral saliva.

A step by step guide to the process is shown below.

- The new design is drawn up, with detailed measurements and intricate details.

- The mould of the new hardware is then made.

- The metal, which is heated to almost liquidation, is then poured into the mould.

- Once the hardware is set, it’s ready to be carefully taken out of the mould.

- Each piece is rasped by hand or machine, to create a smooth surface.

- Once the item is smooth, is is machine polished, to create the shine and colour, seen on all hardware ready to purchase.

- The end product is ready to be stitched onto bridles, or other leather. The bits are now ready to be soldered to the mouthpiece.

Pieces of Art

These stunning pelham bits are more expensive than usual bits – BUT it is very important to appreciate they are limited in numbers and they are extremely special handmade pieces made to order. What’s more they can be personalised with your own choice design on the side. If you look at the drawings you will see they includes the design for the crest of the Portuguese school of Equestrian Arte. Many breeders in Portugal have their stud brand on the side but you can literally create what you want. These bits are vintage, authentic but with modern touches such as the shank is shorter.

You will not be able to find these pieces anywhere else – the Victorino family have had the moulds in their family for many many years.

Having one of these bits in your collection and on your Victorino Bridle is very special! Without a doubt a collectors piece.

The quality speaks for it’s self!

To look at the Bit Collection go to our SHOP or if you would like to talk with us about the pieces and your own designs email us